| Base isolation is the cutting

edge solution used by architects and engineers worldwide to

protect buildings, bridges, and other structures from the

damaging effects of earthquakes.

Seismic base isolation works by de-coupling

a structure from seismic ground motions and vibrations, thereby

eliminating or dramatically reducing the path through which

damaging shock waves and vibrations can travel.

With the introduction of ISO-Base™ Seismic

Isolation Platform technology, WST is the first to apply these

proven engineering principles to seismically protect nonstructural

building components and equipment.

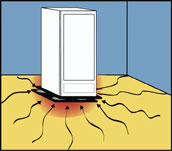

Bolted cabinet without ISO-Base |

Unbolted cabinet with ISO-Base

|

|

ISO-Base technology is the most effective

way to protect your firm's mission-critical and expensive

electronic equipment. A patented "geometry specific"

isolation bearing is used to decouple the equipment (or any

structure) from damaging ground motions.

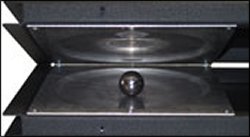

At the heart of the system is the patented

Ball-N-Cone™ seismic isolation bearing, consisting of

two load plates with matching conical recesses sandwiched

over a steel ball bearing.

This unique design allows the platform to

roll smoothly and evenly while accepting input ground accelerations

from any direction. Using gravity as a restoring force, the

bearing re-centers itself as shaking intensity decreases.

The bearing also works as a white-noise filter that virtually

eliminates the transfer of seismic vibrations into sensitive

componentry.

If all other peripheral systems (such as power)

stay up and running, your isolated equipment can and will

continue to operate and process data right on through a major

earthquake.

ISO-Base™ base-isolation technology

passed the intense UBC-Bellcore Engineering Test (R7.5), and

was proven to exceed Seismic Zone 4 Requirements.

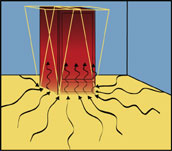

Ball-N-Cone™ Seismic Isolation Bearing |

ISO-Base™ Platform Plank |

|

Traditional rigid fastening methods of bolting

and anchoring equipment to a raised floor or a concrete subfloor

increases the load during seismic activity on the floor anchorage

by as much as 2-1/2 times the item’s weight. Thus, a

1000-pound item could exert up to 2500 pounds of force on

the floor.

ISO-Base™ platforms do just the opposite.

During seismic activity, the floor loading from items placed

on isolation platforms will actually be reduced by 90%; thus,

while in motion, a base-isolated 1000-pound item would exert

only about 100 pounds of force on the floor.

Using ISO-Base technology could mean the difference

between a successful post-earthquake recovery or a major disaster

due to a floor collapse.

|